Kampagnen und Projekte

Energiesparcup

Ab März 2015 traten rund 30 kleine und mittelständische Unternehmen aus Deutschland im Energiesparen gegeneinander an. Bei dem Wettbewerb, der von der gemeinnützigen co2online GmbH initiiert und von der Europäischen Union gefördert wurde, sollen Unternehmen mit bis zu 250 Mitarbeitern Ihren Energieverbrauch senken und damit wettbewerbsfähiger werden.

Energiesparclub

Gefördert durch das Bundesumweltministerium hat co2online Verbraucher im Rahmen der Nationalen Klimaschutzinitiative erfolgreich dazu motiviert, sparsam mit Energie umzugehen. Für das eigens entwickelte Energiesparkonto konnten wir seit 2009 über 100.000 Nutzer gewinnen.

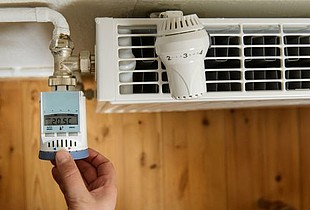

Sparpumpe

Alte Heizungspumpen sind oft echte Stromfresser und bieten Hauseigentümern viel Potenzial zum Geldsparen. Auf den Pumpentausch und den damaligen KfW-Zuschuss hat co2online von 2009 bis 2011 aufmerksam gemacht.

„Feuer sucht Eis“

Millionen deutscher Haushalte sind mit mehr als einem Kühl- und/oder Gefriergerät ausgestattet. Diese Zweitgeräte werden oft nicht benötigt und verbrauchen unnötig Strom. Die Idee des Projekts „Feuer sucht Eis“: Im Rahmen eines Wettbewerbs haben Mitglieder von freiwilligen Feuerwehren, Jugendfeuerwehren und Feuerwehrfördervereinen ineffiziente Kühlgeräte in den Privathaushalten ihrer Gemeinden eingesammelt und entsorgt.

Mehr Orientierung im Sanierungs-Dschungel

Wann lohnt sich eine Sanierung? Unser kostenloses Sanierungshilfe-PDF unterstützt Sie bei der Entscheidung und gibt praktische Tipps